HOW CAN MACHINE LEARNING & Artificial intelligence play a role in making a logistical headache a breeze?

-

Inventory management is the process of overseeing and optimizing a company's stock of materials or products to ensure they have the right amount at the right time while minimizing costs. It involves tracking inventory levels, efficient ordering, and utilizing technology to enhance overall operational efficiency.

-

Ikea hires logistical personnel to monitor and record deliveries. As a rule of thumb, companies find that the more hands touch the product, the more costs are associated with it.

IKEA’s store operations are supported by high-flow facilities (focused on the 20% of SKUs that account for 80% of the volume) and low-flow warehouses that are more manual as compared to its high-flow warehouses.

-

IKEA inventory is stocked at night after opening hours, the logic of its min/max settings is based on the number of products that will be sold from the reserve stack of the bin in a single day or two-day period. The process meets customer demand while minimizing ordering too few or too many products.

WHY ARE WAREHOUSES STILL STUCK IN THE DARK AGE?

BENEFITS OF INVENTORY MANAGEMENT

Inventory management is an important process that should be implemented in warehouses and has a wide array of benefits

It promotes the overall customer experience.

It drives inventory control

A critical part of many businesses.

It helps businesses meet regulations and standards.

Accurate purchase records

Notifications on stock

Barcode identification

Warehouse performance

Sales forecast

Reports and Sale History

CONCERNS

The current method process of inventory management in these distribution centres is primarily analogue and on paper. It is yet to be automated, and with the current method, it is inefficient, unsafe and painfully slow.

-

Walking around and physically tabulating inventory is a laborious task that is highly inefficient.

-

When a product is stored high up employees need to climb up ladders to keep track of inventory.

-

Coupled with the other two reasons, physically scanning inventory is a long and slow process,

For this process, a drone is cost-effective, more efficient and performs better than any human doing the same job. It can perform tasks even with people moving around and will not cause any harm to them. The data can be sent to a central hub, where managers can keep track of all information, and enable the distribution centre to run at its optimum capacity

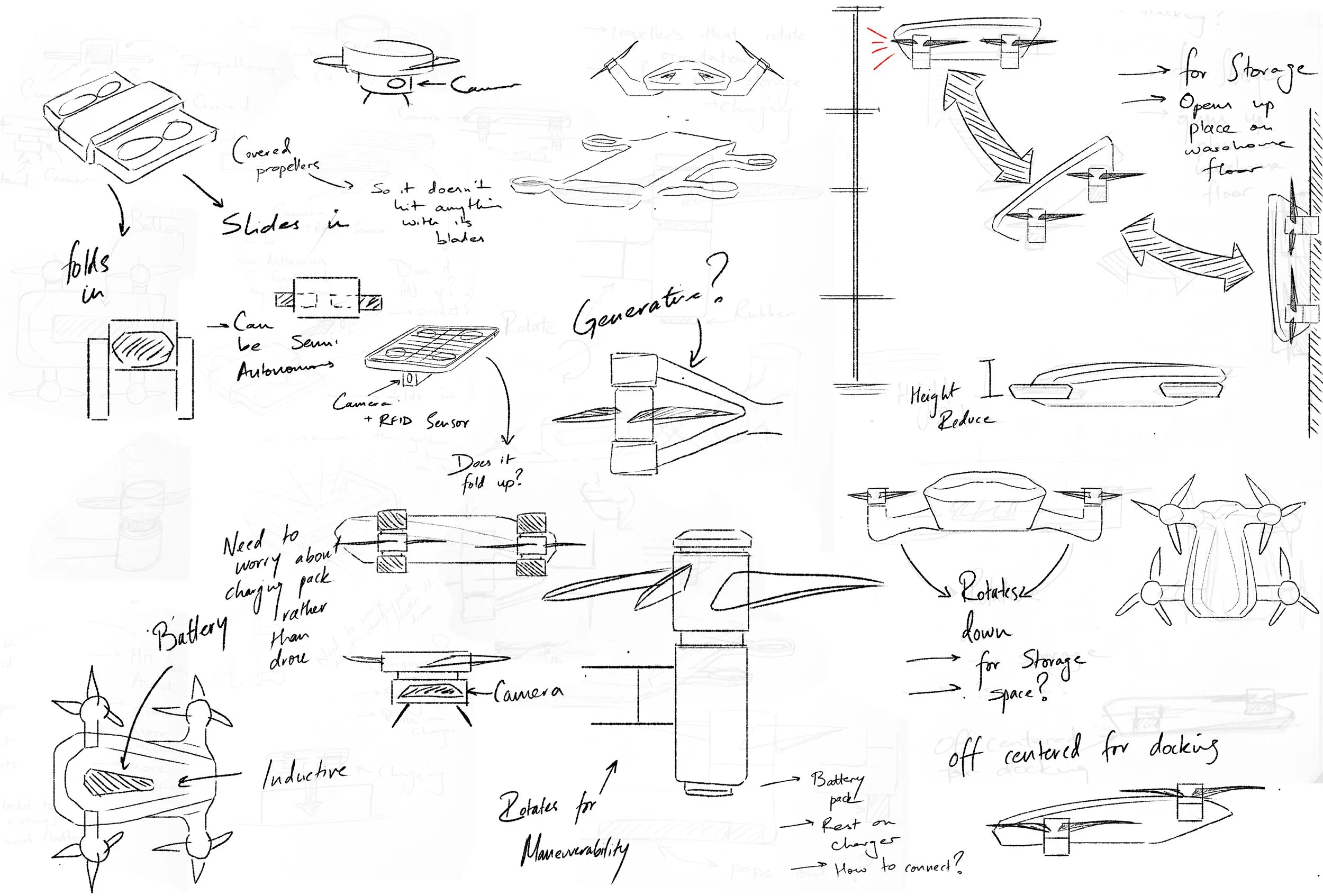

IDEATION

TEchnology that inspires emotion

That is what Sony strives to design products for and towards, it is that feeling that I would like to evoke in the design of this product and Sony is the perfect brand to design for. They have cumulated a product catalogue that has a sleek, clean and functional aspect that I would like to bring to this product. With regard to AI and Sensing technology, Sony is the leader in camera technology and this is a perfect opportunity to start the Drone Division for Sony.

BOXY UNCONVENTIONAL

-

A chunky boxy form with blades that branch out from it with circular, protected form.

CURVY CONNECTION

-

A more drone like structure, with a consumer tech feel with a more streamlined form.

A COMBINATION OF BOTH

-

Yeah, just a combination of the prior two contrasting directions. A boxy form that has an open blade form

ATTACHMENTS

No two warehouses are the same, and the main benefit of this modular attachment is for the sole purpose of being able to add different combinations of camera lenses, sensors and even varying battery capacities.

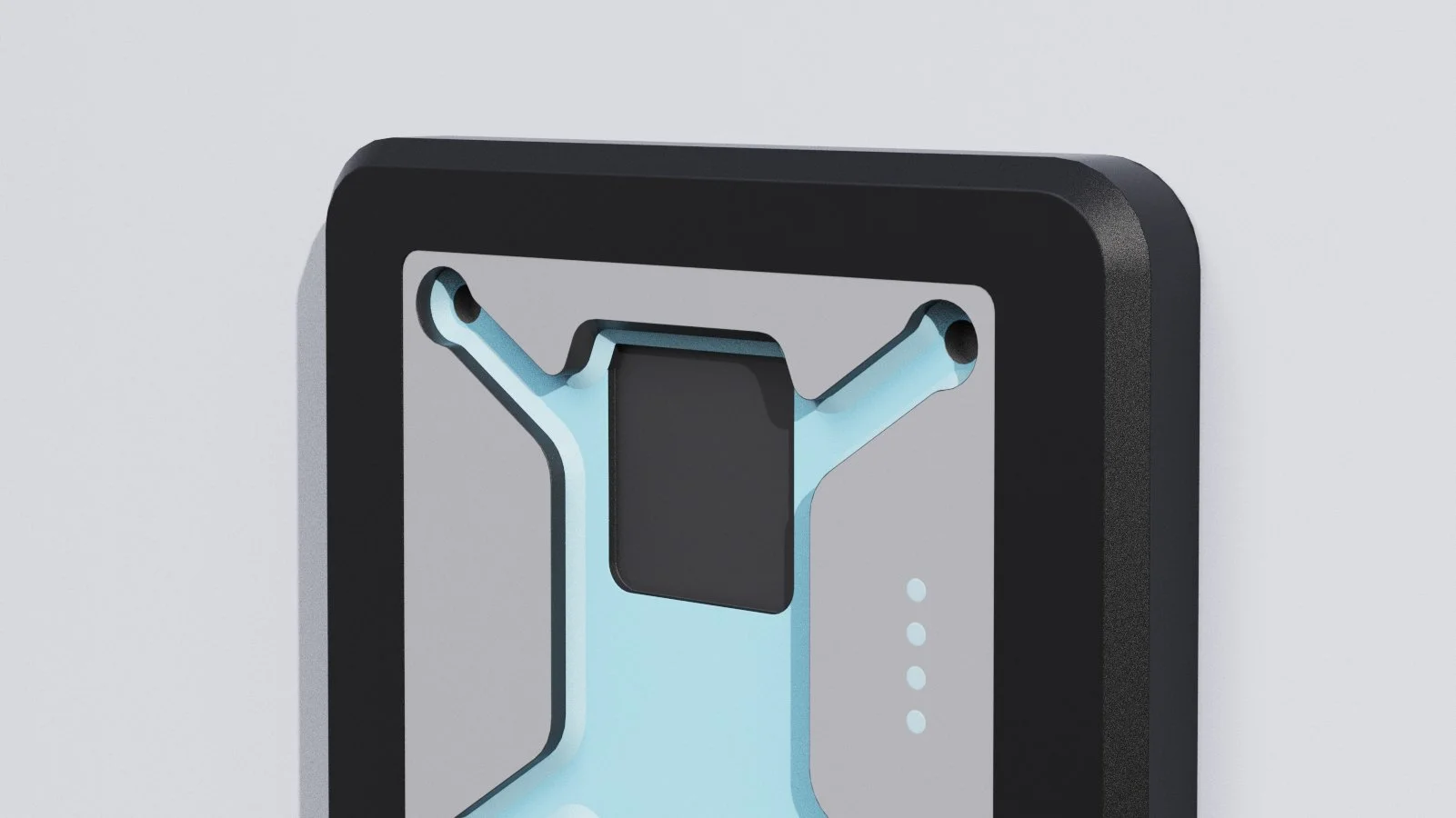

POWER

It’s got to charge somehow right?

In a warehouse, it is not space-efficient to have things charging on a desk or have a bunch of these plugged into a wall. So, might as well take advantage of empty wall space, and get multiple chargers on a wall.

STEP 1: SELECT PATH

With the use of the touchscreen on the top of the device, select the area of the warehouse that the drone should target for inventory management.

STEP 2: SCAN

Post path selection, the drone will start to take stock of what product is available on the shelves. During the first pass of the warehouse, the drone will scan everything to take note of what is in the warehouse. With each ensuing pass, the speed and efficiency of the process will increase.

STEP 3: DATA PROCESSING

The data collected from the drone, is sent to a central hub/computer, where workers will be able to keep track of their inventory all in one place, while also using AI and machine learning to detect patterns and optimize the warehouse's flow of inventory.

SIZE

It is definitely on the smaller side, but big enough to see it flying above you.

BRAND APPLICATION

Customization is key, and a great way for companies to adopt such a product would be by slapping their brand on it and making it look pretty.