Inventory management sits at the core of efficient retail operations, ensuring the right products are available at the right time while minimizing cost and waste. At IKEA, this system is supported by a mix of high-flow facilities that handle the small percentage of SKUs responsible for the majority of volume, and low-flow warehouses that rely on more manual processes. Logistical personnel track deliveries and stock movement, operating on the principle that every additional human touchpoint increases cost, complexity, and the chance of error.

Despite this scale and sophistication, much of warehouse inventory management remains rooted in analogue methods. Stocking is carried out overnight, guided by min/max logic based on short-term sales forecasts, a system designed to balance availability with overstock risk. While effective in meeting customer demand, this approach depends heavily on manual checks, paper records, and slow, repetitive labor, raising concerns around efficiency, safety, and long-term scalability. The question becomes unavoidable: why are warehouses still operating with tools that belong to another era?

This project explores a shift from manual inventory tracking to an automated, data-driven system using autonomous drones. By reducing human dependency for routine monitoring, drones offer a faster, safer, and more cost-effective alternative, capable of operating alongside people without disruption. Real-time data collection, centralized reporting, and accurate stock visibility enable better forecasting, improved warehouse performance, and a smoother customer experience. The goal is not just automation, but a rethinking of inventory management as an intelligent, adaptive system designed for modern distribution centers.

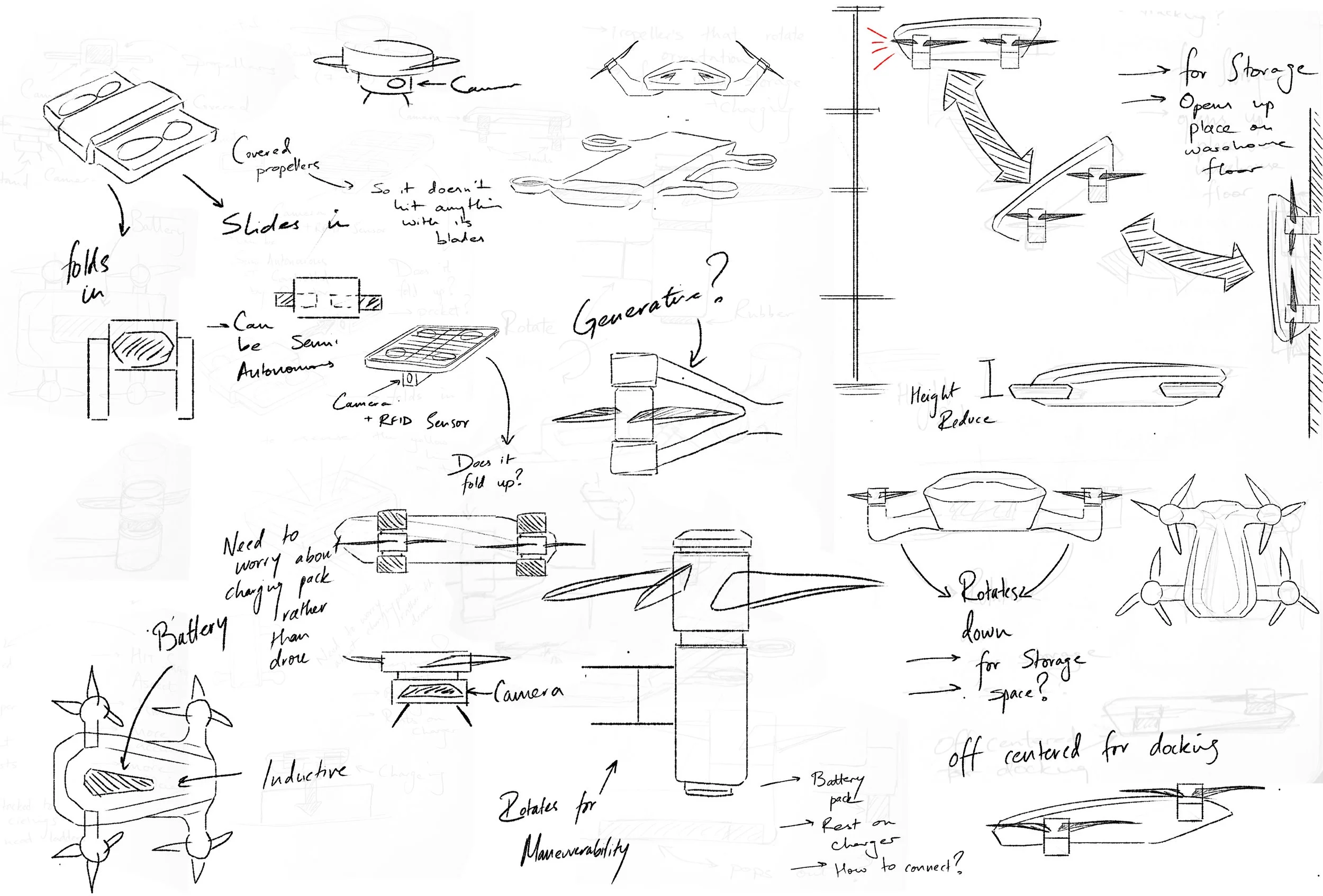

The ideation phase led to three distinct design directions:

Boxy Unconventional

a boxy, unconventional form with protected circular blades;

Curvy Connection

a curvier, more streamlined drone-like structure with a consumer tech sensibility;

Combination

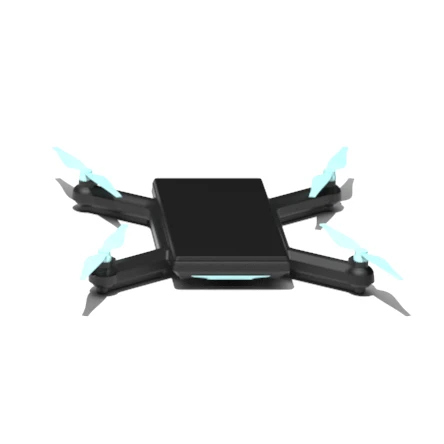

a hybrid approach that merges the solidity of a boxy core with a more open, expressive blade configuration.

Attachments

No two warehouses are the same, and the main benefit of this modular attachment is for the sole purpose of being able to add different combinations of camera lenses, sensors and even varying battery capacities.

process

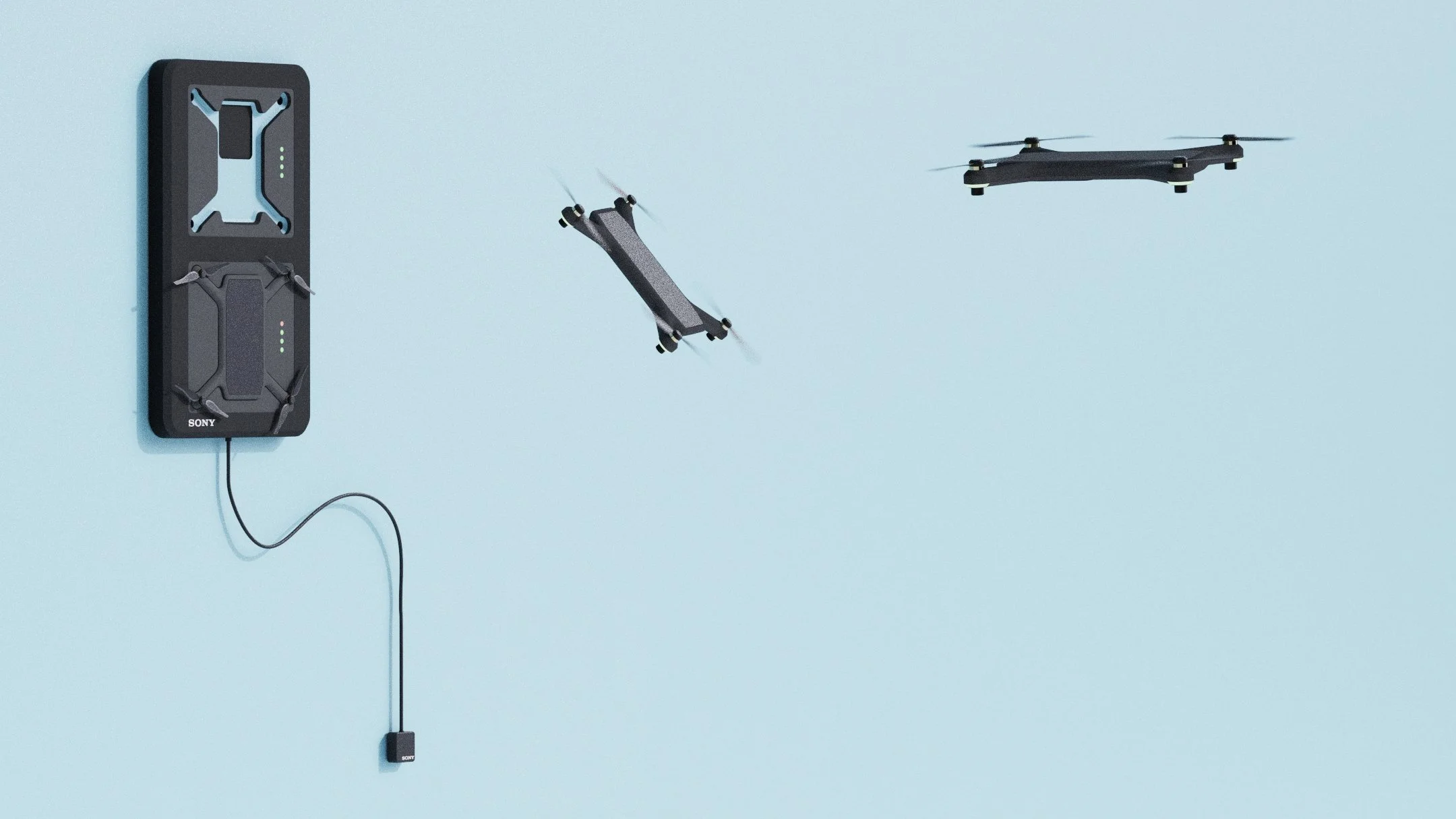

This project proposes a streamlined three-step workflow for autonomous inventory management, designed to minimize manual intervention while improving accuracy and efficiency within warehouse environments. Using the touchscreen interface on the device, a worker first selects the specific area of the warehouse the drone should target, defining the scope of the scan. The drone then autonomously navigates this path, scanning shelves to record available stock, establishing a baseline inventory on the first pass and increasing speed and efficiency with each subsequent run. All collected data is sent to a central hub, where inventory is consolidated into a single system and analyzed using AI and machine learning to identify patterns, support forecasting, and optimize the overall flow of inventory.

size

A compact drone is particularly well suited to warehouse inventory management, where tight aisles, tall shelving, and active workflows demand precision and adaptability. Its small footprint allows it to navigate confined spaces and operate safely alongside workers without disrupting daily operations. By reducing reliance on manual checks and heavy equipment, the drone lowers operational risk while enabling frequent, real-time scans that improve accuracy, visibility, and overall warehouse efficiency.

Why Sony?

Sony’s design philosophy of technology that inspires emotion serves as the foundation for this project. Beyond performance and precision, Sony products are defined by a sense of clarity, restraint, and confidence, where advanced technology is expressed through clean, purposeful form. This project aims to translate that same emotional resonance into a functional, industrial context, designing a product that feels intuitive, refined, and quietly powerful rather than purely utilitarian.

Sony’s extensive product catalogue demonstrates a consistent commitment to sleek, functional design rooted in user experience. That visual and material language informs this concept, shaping an object that communicates trust, intelligence, and approachability. By drawing from Sony’s established design DNA, the product aligns with a brand known for balancing technical complexity with simplicity and elegance.

With deep expertise in imaging, sensing, and AI-driven technologies, Sony is uniquely positioned to extend this philosophy into autonomous systems. This project frames the drone not only as a tool for efficiency, but as an opportunity to establish a dedicated drone division that leverages Sony’s leadership in camera technology and intelligent sensing. In doing so, it positions the drone as an emotionally considered piece of technology, one that reflects Sony’s ability to humanize advanced systems through design.

HOW CAN MACHINE LEARNING & Artificial intelligence play a role in making a logistical headache a breeze?

The goal for this project was to understand the ins and outs of various cultures, ranging from their geography to their activities and way of life, to find similarities and differences that exist between a selected triad of cultures.

July 2021